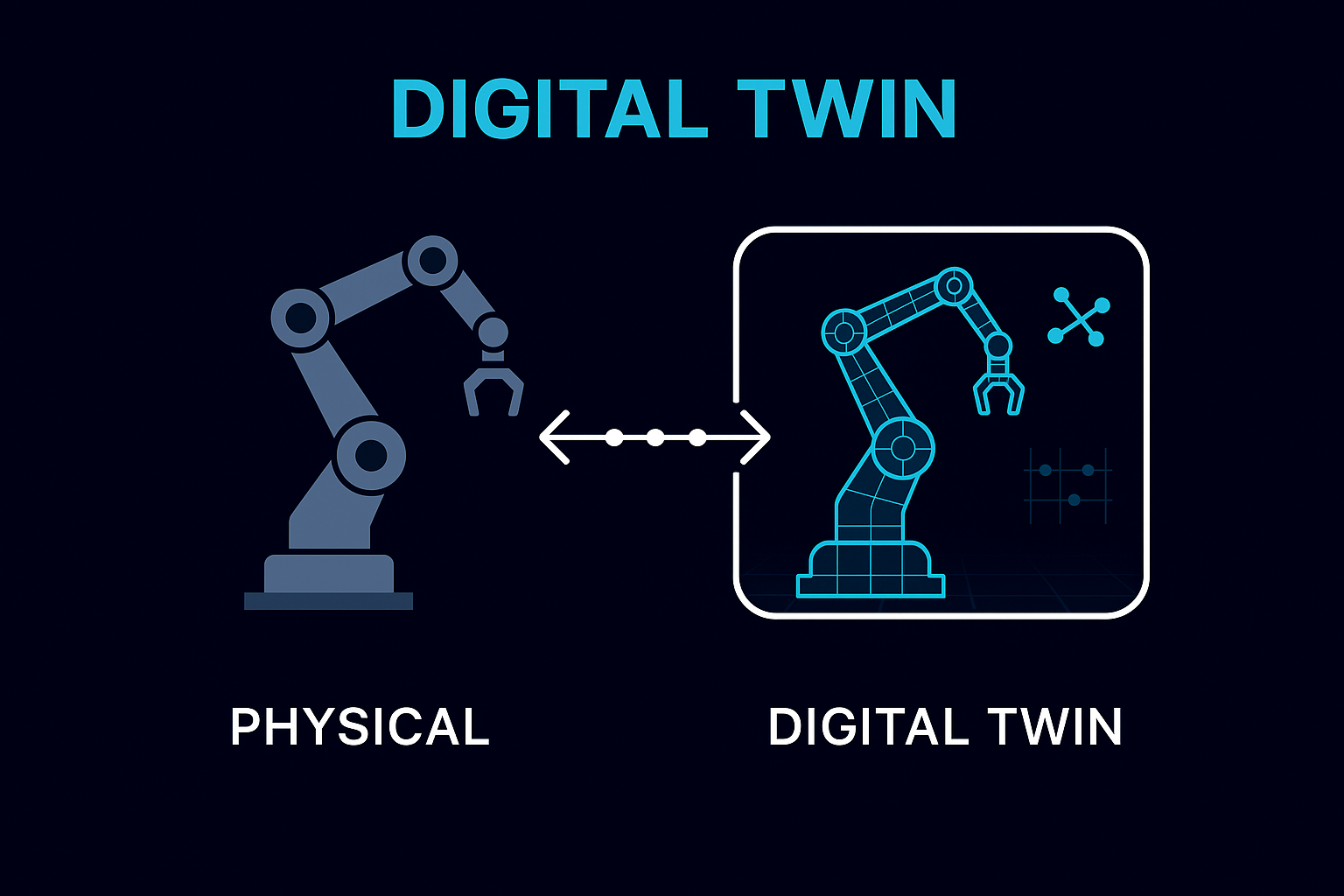

What is a Digital Twin?

A digital twin is a virtual replica of a physical asset—synchronized in real-time with its real-world counterpart. It captures geometry, kinematics, sensor configurations, and behavioral models so teams can visualize, simulate, and control physical systems from anywhere. Unlike static 3D models, digital twins are alive: they reflect the current state of the physical asset and can receive commands that affect the real world.

Anatomy of a Digital Twin

Living Synchronization

Digital twins maintain bidirectional synchronization with physical assets. Telemetry flows from the real world to update the virtual state, while commands flow from operators and autonomous systems to control the physical asset.

Continuous Synchronization

- Joint positions & velocities

- Sensor readings (camera, LiDAR, force)

- System health & diagnostics

- Task status & events

- Motion commands & trajectories

- Configuration updates

- Firmware & policy deployments

- Mission assignments

From CAD to Deployed Twin

Cyberwave's asset pipeline ingests standard formats and produces simulation-ready twins without manual conversion. Upload once, deploy anywhere.

Asset Pipeline

Twins in the Catalog

The Cyberwave catalog contains pre-built twins for common robots, sensors, and equipment. Drag them into your environment and they're ready to use—kinematics, sensors, and control interfaces included.

Example Twins from Catalog

Browse full catalog

Simulation Powers

Digital twins unlock powerful simulation capabilities—from physics-accurate testing to massively parallel RL training environments.

Simulation Capabilities

Rigid body dynamics, collisions, friction, and contact forces

Synthetic camera, LiDAR, depth, and IMU data generation

Speed up, slow down, pause, and step through simulations

Run parallel simulations with different conditions

Capture and replay simulation runs for analysis

Thousands of parallel environments for RL training

Why Digital Twins Matter

- ✗Test on real hardware onlyRisk of damage, limited iterations

- ✗Manual commissioningWeeks of on-site configuration

- ✗No visibility when remoteWait for reports or travel on-site

- ✗Sequential workflowsDesign, build, test in series

- Validate in simulation firstUnlimited safe iterations

- Pre-configured deploymentsDeploy tested configurations instantly

- Real-time visibility everywhereMonitor and control from any location

- Parallel developmentTeams work simultaneously on virtual assets

See Digital Twins in Action

Explore how organizations use digital twins for construction monitoring, reality capture, and simulation-first development.