There's a joke in robotics: the future is always five years away. We've been saying "autonomous everything is coming" since 2015. And yet, walk into any shipyard, wind farm, or construction site in 2025, and you'll find the same scene—humans doing dangerous work, clipboards in hand, expertise locked in their heads.

Why?

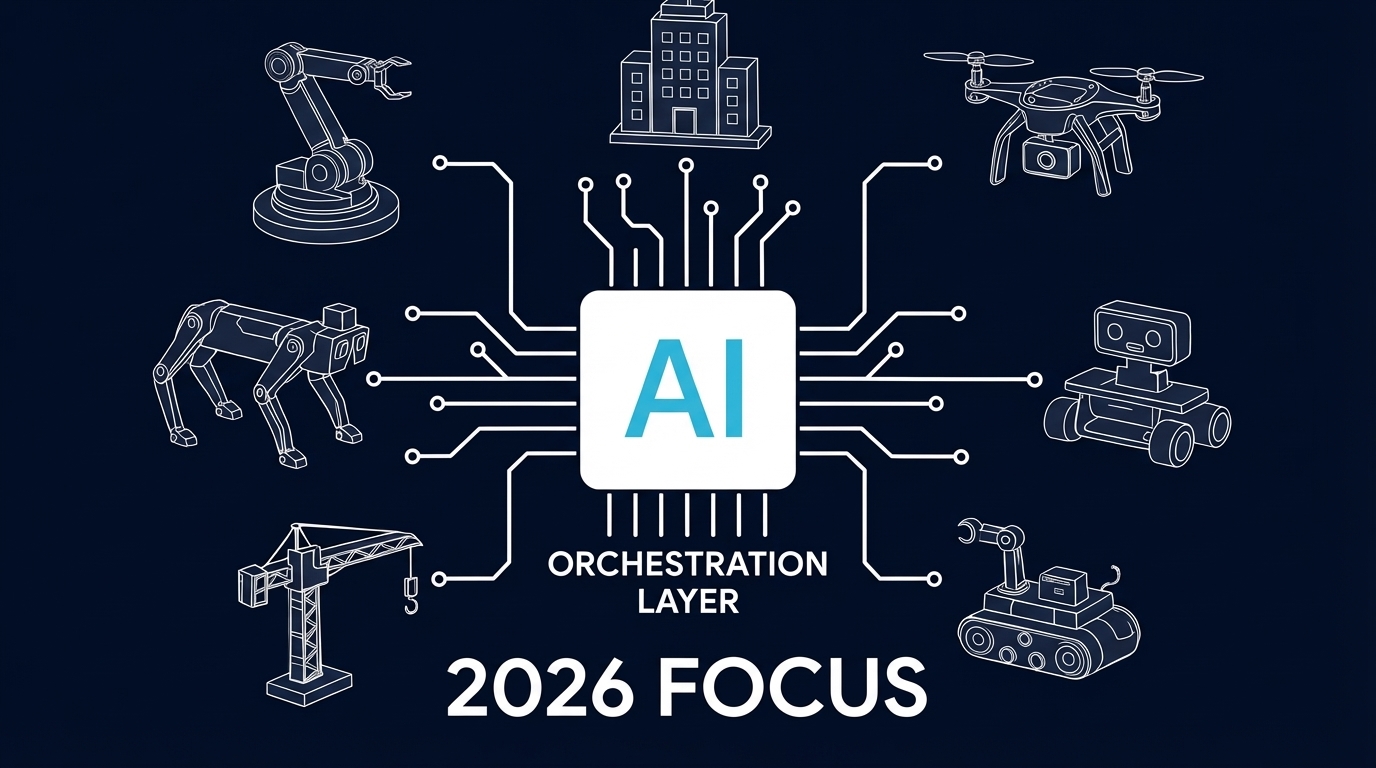

Not because robots can't move. Boston Dynamics solved that years ago. Not because AI can't see. Vision models are shockingly good now. The gap isn't in capability. It's in orchestration.

A robot that can paint a yacht hull is useless if it can't coordinate with the crane operator, adapt to yesterday's weather delay, or hand off to the inspection drone when it's done. Individual robots are tools. What industry needs is a system.

That's what we're building at Cyberwave. And that's what shapes our focus for 2026.

First principles: what actually needs to change

Before talking trends, let's talk physics. Industrial operations have three fundamental constraints:

- Humans shouldn't be where it's dangerous. Full stop.

- Every custom job costs too much. Because automation only works at scale, supposedly.

- Nobody knows what's actually happening. Data exists in silos, on paper, in people's heads.

Every "trend" worth pursuing in 2026 must attack at least one of these constraints. Everything else is noise.

Constraint #1: get humans out of harm's way

Here's a number that should bother you: workers still die every year inspecting confined spaces, climbing wind turbines, entering tanks with residual chemicals. These aren't edge cases. They're Tuesday.

Autonomous inspection isn't a "nice to have." It's an ethical imperative that happens to also make economic sense.

The technology exists. Quadrupeds with thermal cameras. Drones with LIDAR. Crawlers that can enter spaces humans physically cannot. What's missing is the integration layer—the system that takes sensor data from a robot, contextualizes it against the asset's history, flags anomalies, and triggers the right response.

We're not building robots. We're building the nervous system that makes robot fleets useful.

2026 focus: Deploy integrated inspection workflows for confined spaces and hazardous environments. Not demos. Deployments. Measured in hours of human exposure eliminated.

Constraint #2: make automation work for batch size one

Classic automation logic: if you're making 100,000 identical parts, a robot makes sense. If you're making one custom yacht, hire craftsmen.

This logic is breaking.

Two things changed: AI-driven perception (robots can now see and adapt to novel geometry) and software-defined motion planning (you don't hard-code paths anymore—you define goals).

A robot painting a yacht hull doesn't need to know every curve in advance. It needs to perceive the surface, plan the coverage, and execute. Same robot, different yacht tomorrow. Same robot, different task next week—maybe sanding, maybe coating, maybe inspection.

The constraint was never the robot arm. It was the brittleness of the software telling it what to do.

2026 focus: Prove out robotics for high-value, low-volume work—starting with marine maintenance and expanding to construction. The metric isn't "robots deployed." It's "jobs that were manual yesterday, automated today."

Constraint #3: know what's actually happening

Walk into a construction site. Ask where all the equipment is. Ask what got done yesterday. Ask what's blocking tomorrow's schedule.

You'll get answers. They'll be wrong, or incomplete, or three days stale.

Digital twins get hyped as "virtual replicas." That framing misses the point. A digital twin isn't a 3D model. It's a live system of record for the physical world.

When a drone surveys a construction site every morning and updates the twin, you're not doing "visualization." You're eliminating the information gap between what's planned and what's real. That gap is where delays are born, where cost overruns hide, where accidents wait to happen.

The twin isn't the product. The situational awareness is the product.

2026 focus: Move digital twins from "cool demo" to "operational infrastructure." Start with construction and shipbuilding, where the information gap is widest and the cost of being wrong is highest.

The meta-trend: software-defined everything

Here's the pattern behind all three constraints: the limiting factor in industrial automation isn't hardware anymore. It's software architecture.

Factories were designed around fixed processes. Buy a welding cell, program it for Part X, run it for ten years. That made sense when products didn't change and labor was cheap.

Neither is true anymore.

The factories that will win the next decade are the ones that can reconfigure on the fly. New product? Update the workflow. Supply chain disruption? Reallocate resources. That's not a hardware problem. That's an orchestration problem.

We call this the software-defined factory. Not because it sounds futuristic, but because it's the accurate description: the physical assets become interchangeable; the software defines what they do.

2026 focus: Build the orchestration layer that makes this real. Not just for robots—for mixed human-robot teams, for logistics, for quality control. One platform, configurable via software, adaptable in real time.

What we're not doing

Focus means saying no. Here's what we're deliberately not chasing in 2026:

- Betting on a single form factor. We're not building for humanoids alone, or quadrupeds alone, or drones alone. Industrial automation needs diverse morphologies for diverse tasks. Our platform is form-factor agnostic by design.

- "AI agents" that replace humans. The goal is augmentation, not replacement. Humans make decisions; systems execute.

- Buzzword compliance. We won't add "generative AI" to our pitch deck just because investors ask about it. If it solves a real problem, we'll use it. If not, we won't pretend.

The real test

Every trend piece ends with predictions. Here's ours, stated as a testable claim:

By the end of 2026, Cyberwave will have eliminated more than 10,000 hours of human exposure to hazardous industrial environments, while enabling at least three operations that were previously "impossible to automate" due to batch-size-one economics.

That's not a vision statement. It's a commitment.

We'll report back.

The future of industrial automation isn't about building smarter robots. It's about building the system that makes any robot—or any mix of robots and humans—work together on any task, anywhere.

That's the work. Let's get to it.